Railway transportation is a critical component of the global supply chain, providing an efficient and cost-effective way to move goods over long distances. The procedure for transporting freight via rail involves several stages, each designed to ensure the safety, timeliness, and integrity of the shipment. In this article, we will delve into the essential steps involved in the railway transportation procedure, providing insights into how businesses can optimize each phase of the process.

1. The Blueprint: Planning & Coordination

Effective planning is the backbone of any successful railway transportation procedure. This initial phase involves coordinating logistics, selecting the best route, and scheduling the transport to ensure the timely arrival of goods. For example, a company shipping electronics might choose a direct route to avoid delays at junctions, while ensuring that the railcars selected are tailored to the needs of the cargo.

Key Actions:

Determine the origin and destination points.

Select appropriate railcars based on cargo type (refrigerated, flatcars, etc.).

Schedule departure and arrival times, considering potential delays.

Industry Insight: Large logistics companies often use software to simulate different routes and optimize schedules, minimizing delays and lowering transport costs.

2. Ready for Transit: Packaging & Documentation

Proper packaging and documentation are critical to ensuring that goods are transported safely and in compliance with international regulations. The packaging must be robust enough to withstand the journey, while the documentation ensures all customs and legal requirements are met.

Key Actions:

Secure the cargo with appropriate materials (e.g., for fragile goods, use bubble wrap or padding).

Label the goods with accurate descriptions and handling instructions.

Complete necessary shipping documentation, including bills of lading and customs forms.

Real-World Example: A manufacturer shipping automotive parts internationally would ensure that each item is individually packaged with handling instructions to avoid damage. Customs declarations would also be meticulously completed to avoid delays at border crossings.

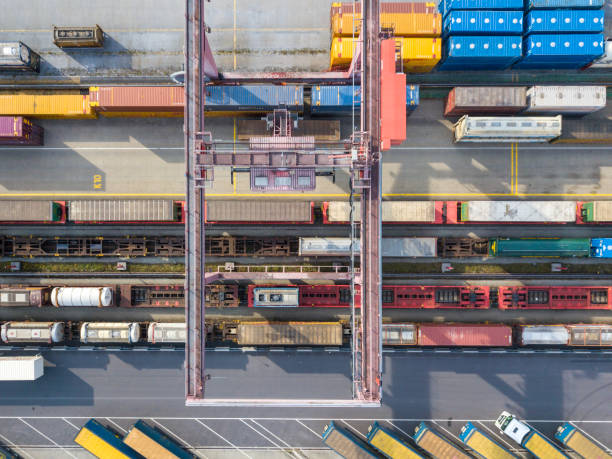

3. The Foundation: Loading & Railcar Preparation

Loading the goods onto the railcars is a vital step, requiring careful attention to the type of cargo and the way it is distributed. Rail operators also inspect the railcars to ensure they are in good condition, preventing potential issues that could arise during transit.

Key Actions:

Load goods evenly and securely to prevent shifting during transit.

Inspect railcars for safety, ensuring they are free from defects.

Adjust cargo placement if necessary to optimize space and ensure stability.

Technology Impact: Many railway operators use automated systems to verify railcar conditions and monitor the loading process in real-time, reducing human error and improving efficiency.

4. On the Move: Railway Transportation & Monitoring

With the cargo securely loaded, the train embarks on its journey. This phase is all about monitoring the progress of the shipment and addressing any issues that may arise. Advanced tracking systems now allow for real-time visibility into the location and status of goods.

Key Actions:

Use GPS and RFID technology to track the train’s location.

Monitor environmental conditions, especially for temperature-sensitive goods.

Stay in constant communication with train operators to respond to any emergencies or delays.

Real-World Example: A shipment of fresh produce might require constant temperature monitoring. If temperatures rise above a certain threshold, the logistics team can immediately notify the operators to adjust conditions or reroute the train to prevent spoilage.

5. Clearing Customs: Regulatory Compliance & Documentation

For international shipments, passing through customs is an unavoidable step in the process. Goods must be inspected and cleared before continuing to their destination. Any issues here can lead to delays, so it’s crucial to ensure all necessary paperwork is in order.

Key Actions:

Submit customs documentation and any other required paperwork.

Pay applicable duties and taxes.

Ensure that goods comply with destination country regulations.

Industry Insight: A logistics manager at a multinational company might work closely with customs brokers to pre-clear cargo, reducing potential delays during cross-border transport.

6. Destination: Unloading & Final Delivery

Upon arrival at the destination, unloading and delivery are the final stages of the railway transportation process. Efficient unloading procedures are essential to ensure the goods are handled carefully and that the transfer to another mode of transportation (such as trucks) is seamless.

Key Actions:

Unload the cargo using safe and efficient methods.

Inspect the goods for any damage during transit.

Transfer the goods to their final delivery mode, ensuring timely arrival.

Real-World Example: A retailer receiving a shipment of electronics might inspect the boxes for damage before transferring them to trucks for final distribution to stores across the country.

7. Wrap-Up: Final Inspection & Documentation

Before the process is officially complete, a final inspection ensures that all goods have arrived in good condition. This stage also involves completing any remaining paperwork and filing any necessary claims if damages occurred during transport.

Key Actions:

Conduct a final inspection of the goods.

Complete delivery documentation, including proof of delivery and condition reports.

Address any discrepancies or damages through claims or insurance processes.

Industry Insight: For high-value shipments, businesses may conduct a detailed audit at the destination point to verify that all items were delivered as promised

Conclusion: Streamlining the Railway Transportation Procedure

The railway transportation procedure is a multi-faceted process that demands careful attention at each stage. By understanding and optimizing each step—from planning and packaging to unloading and inspection—businesses can streamline their logistics operations and ensure efficient, safe, and timely delivery of goods. By leveraging technology, improving coordination, and adhering to industry best practices, railway transportation continues to be a vital, reliable mode of transport in the global supply chain.